Description

Introduction

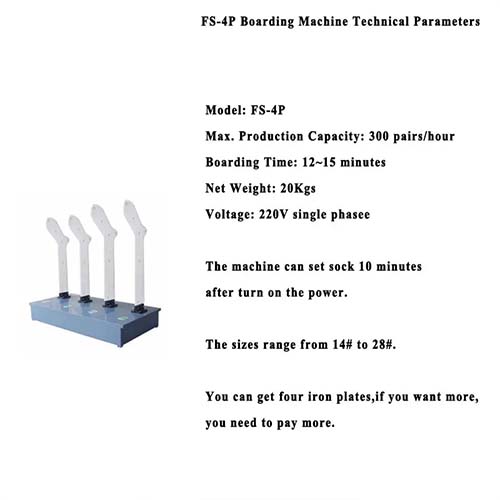

1. Working Principle: This sock boarding machine(sock setting machine) is electronic type, which is using electricity of single phase 220V, 50HZ.

Machine is working through the heat from the iron form, whose temperature can be adjusted, and heat is uniform, and is with electricity leakage protection.

2. Usually our sock boarding machine can work after 10 minutes when power is on

3. The actual power per sock form is about 100W~250W according to different sizes of sock forms

4. One operator can handle 4~8 pcs of sock form, it takes only 8~10 seconds after sock is on sock forms according to different material of socks

5. Production Capacity: one operator can handle 200~300 pairs( according the different sizes of socks) per hour

6. Flexible: all kinds of sock form can be installed on the same machine, it also takes less working space

7. Application: All kinds of socks can be ironed: plain socks, terry socks, thicker socks, five-toe socks, two-toe socks, vertical 3-D socks etc.

8. Special sock forms can be made according to buyer’s requirements.

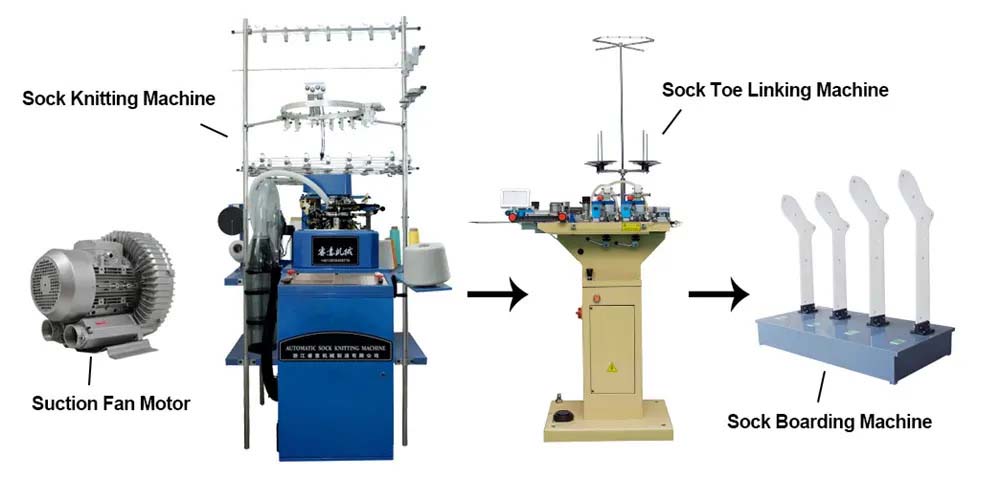

Sock Production Line

This machine is also called sock ironing/ forming machine which makes the socks flat and no wrinkles.

There are some different types can be choosen: simple sock boarding machine with 4 forms, box steam sock boarding machine, rotary steam sock boarding machine. It depends on the production capacity of socks machines. Normally, a simple sock boarding machine can support about 10 sets socks machines.

Reviews

There are no reviews yet.