Description

| 3.75 Inch Plain & Terry Socks Knitting Machine Technical Specification | ||

| Model | HF-6FTP | |

| Diameter of Cylinder | 3.75″ | |

| Needle Count: | 96N 108N | Baby Socks |

| 120N | Children Socks | |

| 132N | Teenager Socks | |

| 144N | Ladies or Men’s Socks | |

| 156N 168N | Men’s Socks | |

| 200N | Quality Men’s Socks | |

| Maximum Speed | 280-330R.P.M | |

| Voltage: | 380V / 220V | |

| Main Motor | 1.3KW | |

| Fan | ≥1.1KW(Optional) | |

| Gross Weight | 300KGS | |

| Package Size | 0.94*0.75*1.55M(1.1m³) | |

| Production Capacity | 250-400 Pairs/24 hours according to different sizes of sock | |

Type of Socks can be made:

By Way of Knitting: Plain Socks

By Ages: Baby Socks, Children Socks; Teenagers’ Socks; Adults’ Socks

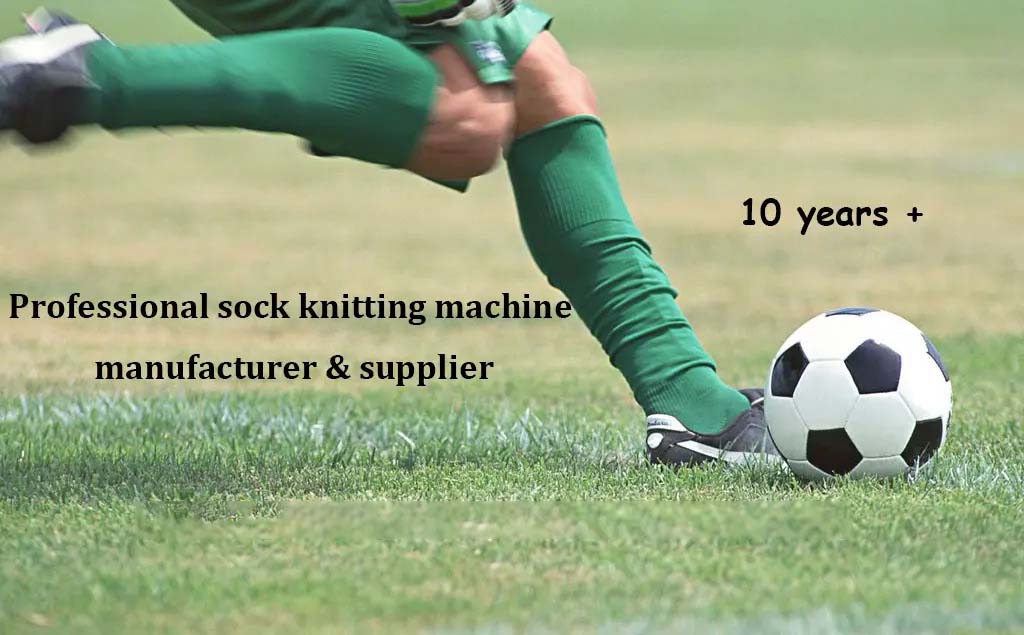

By Sock Styles: Fashion Socks; Business Socks; Sports Socks; Casual Socks; Football Socks; Cycling Socks

By Sock Length: Ankle Socks; Knee High Socks; Over Knee High Socks

By Function: Mesh, Tuck Stitch, Rib, High Elastic Welt, Double Welt, Y Heel, Two-color Heel, five toe socks, left and right socks, bottom toe sewing socks, 3D socks, Jacquard socks etc

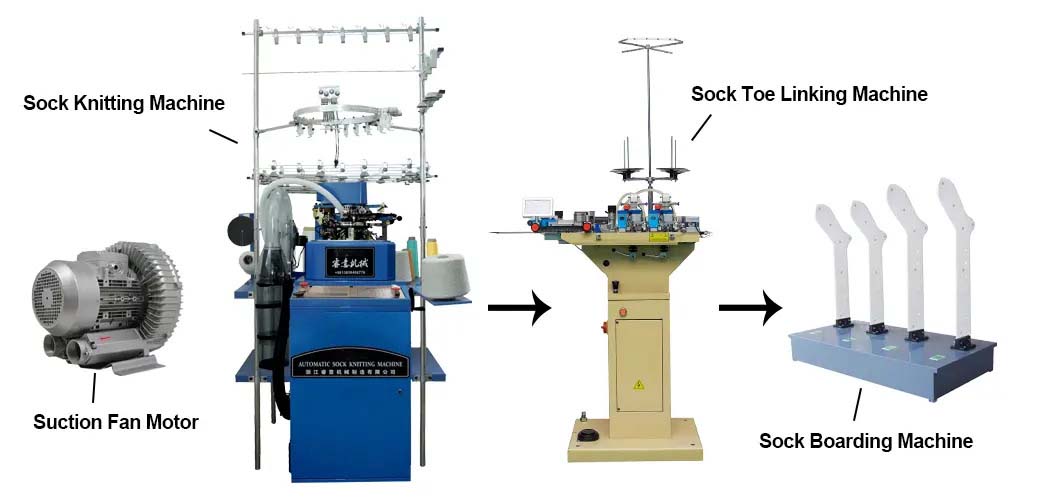

Socks Line Building

Pre-production Equipment:

Air Compressor, Air Compressor Storage Tank, Filter, Cooling Drier, Stabilizer, Suction Fan Motor

The above-mentioned equipment sizes or power will be different according to different quantity of sock machine.

Sock Toe Closing Machine:

One-motor model 181; Two-motor model 282; Three-motor model 383; Five-motor model 585; Six-motor model 686

Sock Boarding Machine:

Electrical Sock Boarding Machine; Box Sock Boarding Machine; Rotary Sock Boarding Machine.

Suitable production line below 10 sets sock machines:

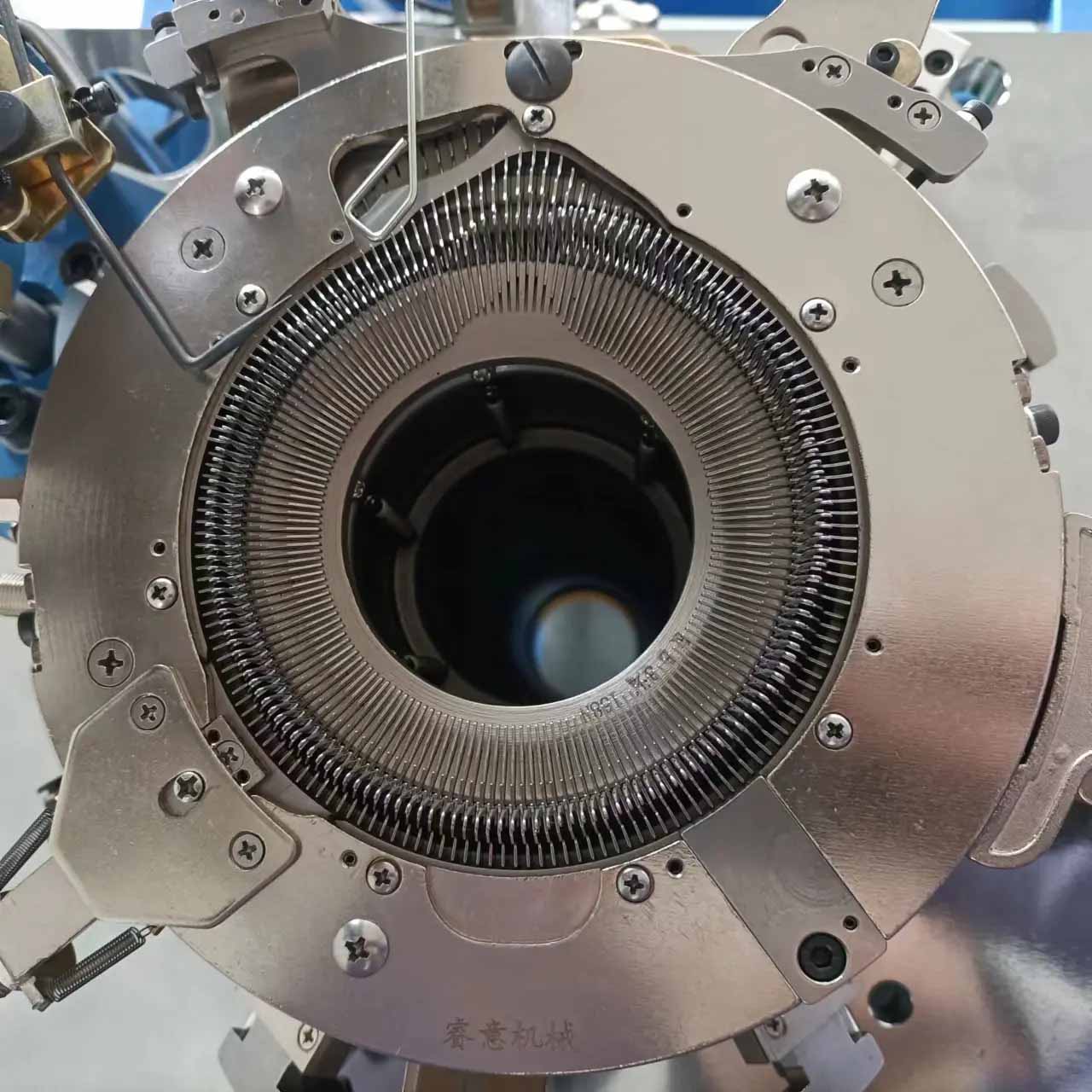

3.75 inch cylinder

As the most important part of socks machine used to knit socks. The diameter cylinder of this model is 3.75 inch. The needle counts of cylinder can be choosen according to the different age group.

Optional Configuration:

1. Suction fan motor 1.1kw (for small quantity of sock machine, below 10 sets, individual suction fan motor is suggested, if over 10 sets, central suction fan motor is better, which can help save electricity consumption greatly)

2. Solenoid on main feeders, sub-feeders, valve box

3. Double elastic motors, double elastic feeders

4. BTSR yarn break sensors

5. LGL or Chinese brand accumulators

6. Robert yarn creel

Reviews

There are no reviews yet.