Description

Rotary Socks Boarding Machine

1. In accordance with the products and work condition, the time of drying, boarding and the steam pressure can be set freely, and the operation is very easy to control.

2. The process of putting socks on is under the paused state, so it is a good condition to setting more excellent socks or other products.

3. It is very rare to be out of order if you operate correctly, at the same time, the running and maintaining of the machine is easy to handle. And this kind of machine is space-saving.

4. As for different types of products, the actually production is above the theoretical data.

This kind of machine is space-saving and with automatic sock-off function, saving manpower and time.

| Model | 4P.S | 5P.S | 6P.S | |

| Capacity (Doz/ h) | Steam Pressure (1.5kg/cm) |

65 | 95 | 120 |

| Steam Pressure (1.8kg/cm) |

60 | 90 | 118 | |

| Steam Pressure (2.0kg/cm) |

55 | 80 | 110 | |

| Steam Pressure (2.3kg/cm) |

50 | 75 | 98 | |

| Steam Pressure (2.5kg/cm) |

45 | 70 | 95 | |

| Cycle Time (group/ sec) | 18-36 | |||

| Operator | 2 | 2 | 3 | |

| Socks Form | 60pcs (15pcs*4groups) | 100pcs (20pcs*5groups) | 180pcs (30pcs*6groups) | |

| Power Requirement | 3.7KW | 3.7KW | 5KW | |

| Air Requirement | 5-7kgf/cm2 | |||

| Steam Requirement | Max 145kg/h | Max 200kg/h | Max 300kg/h | |

| Steam Chamber | 0.148 m3 | 0.172 m3 | 0.252 m3 | |

| Dimension (L*W*H, mm) | 1800*2300*2300 | 2100*2500*2300 | 2800*3200*2300 | |

Spare Parts

We can provide different sizes of sock boards, welcome to contact us!

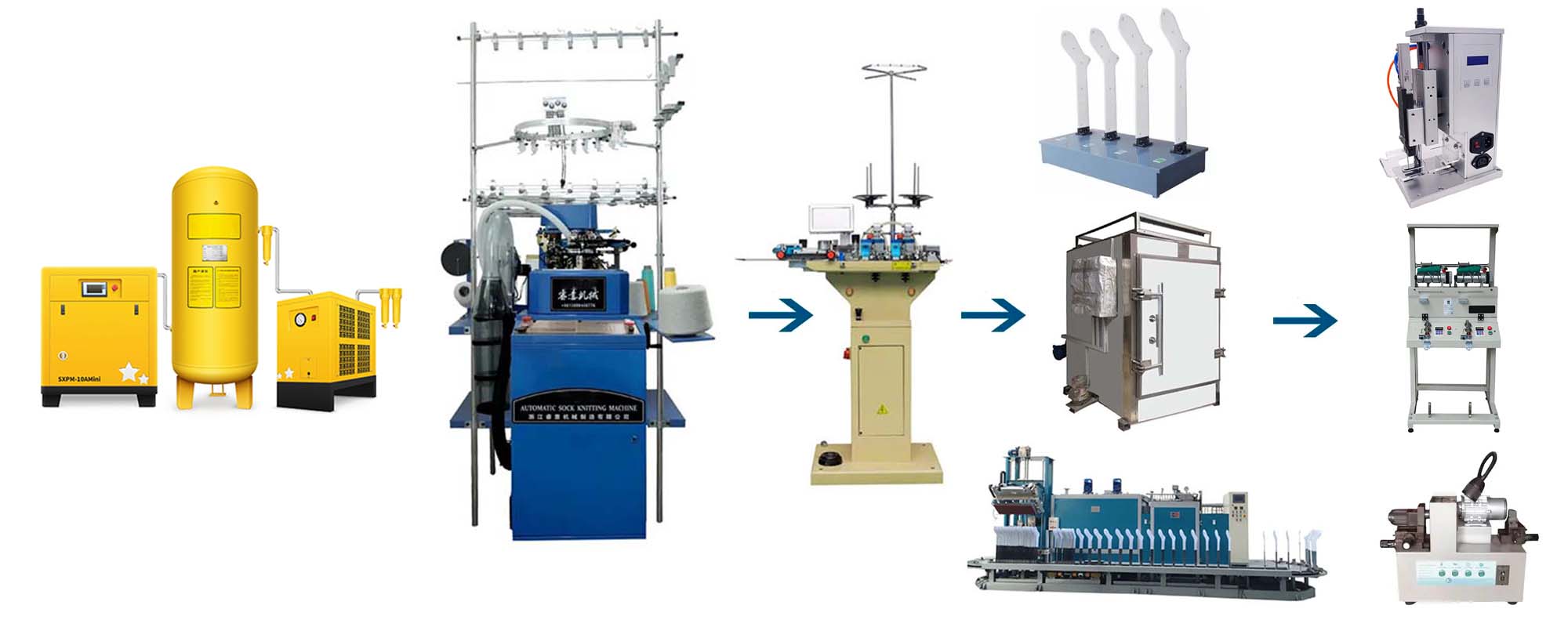

Sock Production Line

We can supply complete socks production line such as Sock Knitting Machine, Sock Linking Machine, Sock Boarding Machine, Sock Yarn, Sock Tagging Machine, Yarn Winding Machine, Air Compressor…

Reviews

There are no reviews yet.