Description

Product Description

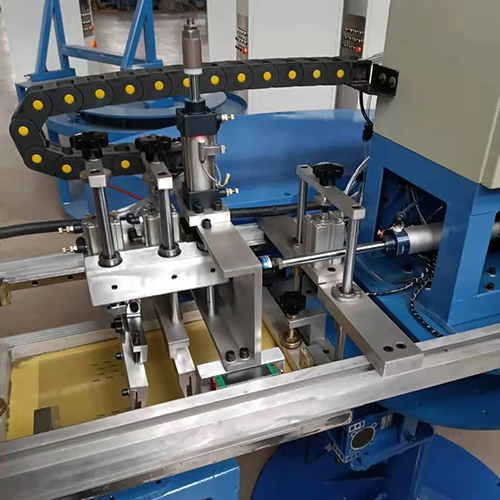

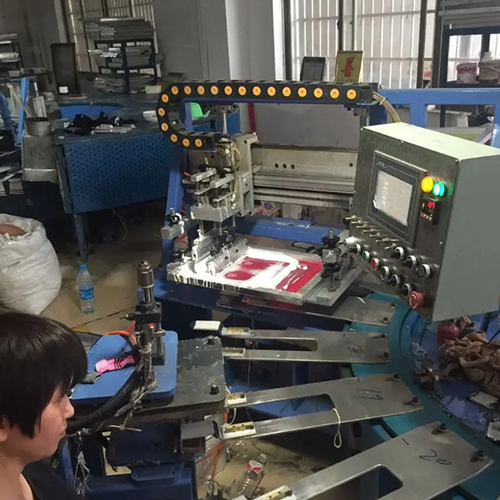

Its main function is to print silk screen printing materials such as PVC or silica gel through knitwear (socks, gloves, scarves, etc.) through screen or hollow board. Add anti-slip, decorative, and printed company or brand logos to the product.

1. Low equipment failure rate and stable quality.

2. Printing speed is 800 to 1800 pairs per hour.

3. Simple operation (only 2 to 3 people), humanized and intelligent.

4. Energy saving, more than 30% energy saving compared with similar products.

5. Fault repair and maintenance is easy to learn.

6. After-sales service is timely and can be controlled remotely. And signed a global warranty agreement with major suppliers such as Yadak, Panasonic, Schneider, and Parker.

7. pre-sales customer service details, and can provide technical guidance and market analysis.

| Model | HF-18PS |

| Size | 2200MM*1900MM*1550MM |

| Work Cycle | 600 pairs/hour(invisible ship socks) 2 people operation |

| 200 pairs/hour(gloves) 1 person operation |

|

| Template Quantity | 18 pieces(9 pairs) |

| Power Requirement | 6KW 380V, 3P, 50/60HZ(Excluding air compressor) |

| Voltage Requirement | 0.5-0.7Mpa |

1. While maintaining the original labor cost, the Anti Slip Dotting Machine not only improves production efficiency to a certain extent, but also reduces electrical energy by 20%;

2. The Anti Slip Dotting Machine has been improved and replaced, and the working performance of this version is very stable. The product produced is very beautiful and very durable.

Detailed

Sample

Reviews

There are no reviews yet.